|

Fastest Samples Guaranteed... Delivered in as low as 9 Days... |

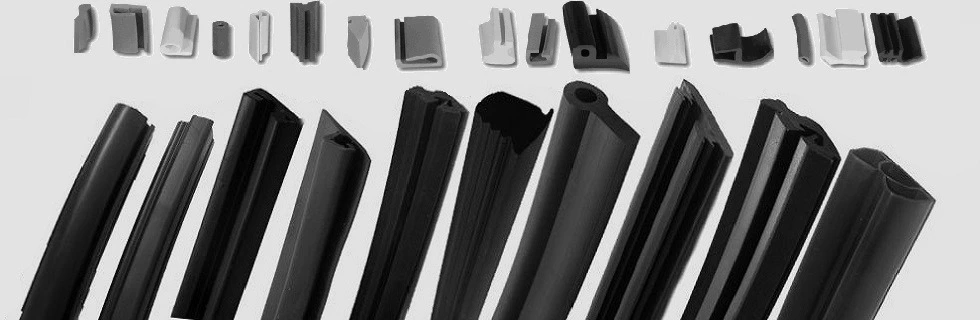

Rubber Mouldings

- Rubber Molding Companies

- Rubber Moulding

- Rubber Molding

- Rubber Trim Molding

- Rubber Base Molding

- Rubber T Molding

- Rubber Compression Molding

- Molded Rubber Parts

- Rubber Moulded Production

- Rubber Mold Company

- Silicone Rubber Mold

- Rubber Molds

- Rubber Molds For Concrete

- Rubber Moulds Manufacturers

- Rubber Mold Making

- Rubber Mold Design

Silicon Moldings

Casting Rubber Products

Custom Products

Gasket Products

Other Rubber Products

- Silicone Rubber Products

- Compression Molding

- Rubber Products

- Rubber Products Manufacturers

- Industrial Rubber Products

- Masking Rubber And Silicone

- Rubber Tube

- Rubber Tubing

- Rubber Hose

- Rubber Extrusion

- Custom Extrusion

- Rubber Mounts

- Rubber Couplings

- Rubber Roll

- Rubber To Metal Bonding

- Rubber Components Manufacturers

- Rubber Bellows

- Rubber Bushing

Polymer Molding Products

Seals Rings and Washers

Industries We Serve

Benefits with Rubber Molded Products

Quality Product

Ontime Delivery

IP Protection

Design and Engg. Support

CRM for Regular Updates

Above All -

Your PEACE OF MIND!!!

Silicone Compression Molding In Chester Pa, Pennsylvania

What is Custom Silicone Compression Molding?

Custom compression molding of silicone is one of the most productive methods for manufacturing high-quality durable silicone products, such as medical devices or automobile parts. Silicone rubber is molded in a compression process and used for manufacturing highly flexible, but solid parts. This technique is a reliable and effective way to make complex geometries, durable components, and products where precision is required. We now will discuss the complete process of silicone compression molding, the role of the silicone compression mold manufacturer, and its applications and benefits, from medical silicone molding to using it for other types of molds.

We are one of the best manufacturers of silicone compression molds. We are highly skilled in the production of high-performance products with advanced compression molding techniques. We have years of experience in custom silicone compression molding services, providing accurate and effective products across many industries.

Benefits of Custom Silicone Compression Molding

Custom silicone compression molding provides a high number of benefits, which are useful for many applications.

- High Precision: It can produce finer and even the most intricate shapes that result in excellent dimensional stability.

- Durability: It is resistant to extreme temperatures, chemicals, and UV exposure.

- Versatility: With such material, very wide ranges of different products are manufactured-all the way from seals and gaskets to medical appliances and auto parts.

- Cost-Efficiency: Compression molding can easily be used for either low volumes or high-volume productions because material waste and tooling expenses are brought down to almost nominal figures.

The Role of a silicone Compression Molds Manufacturer

A silicone compression molds manufacturer only focuses on designing and manufacturing high-quality molds specifically for silicone compression molding. They provide molds based on varied individual client requirements that manifest to achieve accuracy, durability, and conformance in the end product of silicone. They utilize a variety of advanced machining techniques along with expert knowledge of mold making to respond to the growing needs of the automotive, medical and consumer goods industries.

Services Provided by Silicone Compression Molds Manufacturer:

- Custom Mold Design: The manufacturer usually collaborates with the customer to design a custom mold for some particular product specification.

- Prototyping: The mold manufacturers make a prototype for testing the product design and functionality before it goes into mass production.

- Tooling: Several advanced machines and techniques are used by manufacturers to make very accurate mold tolerances with a good surface finish.

- Maintenance and Repairs: Regular maintenance and repair are also provided to ensure optimum performance of these molds for a long time.

What is Silicone Compression Molding Machining?

Silicone compression molding machining is the equipment and technology during compression molding. It can be said that advanced machining tools help in creating detailed mold designs for complex shapes and details in silicone products and parts. Types of machining equipment used in silicone compression molding:

- Compression Presses: The machines are used to apply the pressure required to compress the silicone material into the mold. Modern compression presses are equipped with computers, which control pressure and temperature precisely.

- Mold Heating Systems: This is the most critical aspect in which heating through appropriate systems is required for the curing of silicone. Built-in heating systems are installed in the machining tools so that the mold heats uniformly throughout.

- CNC Machines: CNC machines provide precision machining for molds with pinpoint accuracy. They machine molds with intricate designs without losing any accuracy.

- Trimming/Deflashing Machines: There is a need to remove excess material after the molding process. These are trimmed and defleshed to clean the parts so that they come out with a smooth and glossy finish.

Key Considerations for Compression Molding Products Maker:

Compression molding products makers take up all the stages of manufacturing from designing a mold to the delivery of the final product. Manufacturers produce a wide range of silicone and rubber products through the compression molding technique. Some of the considerations are as follows:

- Material Selection: Manufacturers must select the appropriate material based on the requirements of the application, determining the performance of the resulting product.

- Quality Control: The manufacturer should be very stringent about quality control so that the final product after molding meets expectations both by industries and customers strictly.

- Customization: The manufacturer should also provide the customers with an option of custom design according to their specific needs of color, size, and shape.

Advantages of Silicone Rubber Compression Molding

Silicone rubber compression molding is one of the specific compression molding types where the primary material is silicone rubber. Several inherent properties of silicone rubbers, such as heat resistance, flexibility, and biocompatibility, make the material suitable for a wide range of applications.

Key Industries and Applications:

- Automotive: Silicone rubber compression molding is used to make seals, gaskets, and other parts that require resistance to very harsh environments and high temperatures.

- Medical: Silicone is used in producing catheters, tubes, and seals, and compression molding ensures such products are free from contamination and meet all health and safety considerations.

- Electronics: This industry uses silicon parts for insulation, moisture protection, and damping of vibrations.

- Consumer Goods: Ranging from kitchenware to wearables, the flexibility and durability of silicone make it an almost indispensable component in consumer goods.

- Aerospace: In aerospace applications, the parts survive extreme temperatures and stresses without losing their integrity. Here, compression molding of silicone rubber is very important.

Why Choose Medical Silicone Molding?

The medical industry strictly demands product quality and precision. Medical silicone molding is specifically used for the production of reliable components intended to meet the strict requirements of applications in healthcare applications. Moreover, silicone is biocompatible and is used in medical device components, implants, and other healthcare products that come in direct contact with the human body.

Why Choose US

Silicone compression molding machining is the determinant of preciseness and quality in every part we manufacture. We have sophisticated machining processes that allow us to create custom molds and parts, which meet specific requirements and are independent of complexity. Our machining process includes:

Design Consultation: We work closely with you to clearly understand the needs of your project from the choice of materials right through to the detailed final design.

Prototyping: We make prototypes ahead of a full-scale production to validate the design and get the product right for your needs.

Tooling: We have precision silicone compression molding machining to come up with the highest quality of molds which can face a production process.Production: Our compression molding process can easily make tight-tolerance products of consistent quality.

Quality assurance: All products have to pass rigorous testing to live up to the performance specification required.

Custom Solutions for All Your Silicone Compression Molding Needs

With custom silicone compression molding, quality long-lasting components can be produced for any application. At Rubber Molded Products, we provide end-to-end solutions for all your silicone molding needs with our superb services in silicone compression molding. We do know that each project is unique, and we deliver fully custom solutions for your silicone mold requirement. We have machining experience with silicone compression molding, and a very high commitment to delivery, with quality products on time, so we can assure you every part manufactured will meet exceptional standards of quality and accuracy. The molds are made using state-of-the-art machinery, working closely with clients to ensure every design specification.

We have expertise in handling complex projects, from the initial design phase to final production. Whether you want just one prototype or a large-scale production, we're fully equipped and always up-to-speed to handle orders of all sizes with precision. Contact us today to find out more about how we can help you with your compression molding products and create custom silicone parts that meet specific industry needs.

We Expertise in

Custom Molded Products

Rubber To Metal Bonding

Silicone To Metal Bonding

Injection and Compression Rubber Mouldings

Custom Bellows

Grommets

Diaphrams

Rubber Mounts

Custom Seals and Gaskets